Does Body Armor Expire?

Does body armor expire? Yes and no. Both Ceramic and UHMWPE are relatively inert and don’t have any strong reactions to everyday things. These materials can last for decades without any degradation in performance–much to the chagrin of environmental scientists. However, there are a lot of things you can do that can compromise the ballistic performance of body armor, and critical mistakes manufacturers can make that can move it along. The manufacturer’s warranty period stated on the back of a piece of armor isn’t an expiration date. The NIJ requires that certified products maintain a warranted daily use service life of at least five years, but it’s really more about the wear and tear that determines the serviceable lifespan of your armor.

In the same way that NIJ defined protection standards, the industry generally finds these 5-year warranty guidelines from NIJ useful whether the product is certified or not. We’ve previously covered the finer points of how Ultra High Molecular Weight Polyethylene can ‘go bad’. It’s easily preventable, but advised that with enough wear and tear, you should replace your armor after several years of daily use. Armor manufacturers build our products to the 5 years of simulated daily wear standard, and this is what you should think about when deciding whether to replace your armor.

Does body armor expire? Not necessarily in shelf storage, but there is a limit based on wear and tear created by regular daily use.

What Parts Can Go Bad?

You should know how to care for your armor since it isn’t something you can PM. Also, you should know how that can affect its performance over time in regular use.

Rifle-rated armor has two basic components:

Strike Face

You wear a strike face pointed away from your body. Your strike face is the first surface a bullet impacts. The ceramic provides the greatest level of resistance and weight in your armor. Typically made of Alumina Oxide, Silicon Carbide, Boron Carbide, or Silicon/Boron hybrid ceramic, your strike face’s job is to break up, slow down, and hopefully turn a bullet sideways. Smaller pieces moving more slowly are easier to defeat, and turning a bullet sideways can dramatically degrade the terminal effects of a bullet’s impact–particularly armor-piercing hardened steel or tungsten rounds. NIJ standards are to shoot at a 0-degree perpendicular angle to minimize the chances that a bullet turns and minimize the amount of material it must pass through to defeat the armor, thus maximizing the opportunity for a “worst-case scenario” impact.

High strength ceramics offer a relatively lightweight and affordable way of defeating the vast majority of ballistic threats worldwide with ultra hard compounds. While very strong, they’re also fairly brittle and may be damaged by impacts from other hard materials such as dropping a strike face on cement. Ceramic works in two important ways; the strong chemical bonds provide an efficient method of rapidly turning kinetic energy into heat energy, and its high hardness creates a barrier of such high strength that most bullets cannot survive the impact without catastrophic loss in both velocity and mass retention. This is different than steel-based plates that allow bullets to fragment and ricochet. Ceramic plates very effectively ‘absorb’ the bullet impact like a baseball mitt rather than reflecting it like a bat. This is why ceramic is the choice of actual operators, and steel armor must be sold at extremely low prices.

Backer

If a bullet is strong or fast enough to pass through the strike face, it’s the backer’s job to catch the remaining fragments like a catcher’s mitt. Backers have traditionally been made with para-aramid fibers, ballistic fiberglass, and ultra high molecular weight polyethylene. Today, para-aramid fibers like Kevlar have largely fallen out of use in favor of high strength UHMWPE. Ultra High Molecular Weight Polyethylene provides the same level of protection while using far less mass and volume. Thus, you get thinner and lighter armor. Ballistic fiberglass and polyethylene make up the vast majority of plate backer materials. UHMWPE backers are comprised of variations of the same material found in Level II and IIIA soft armor. Ultra high tensile strength laminate fibrous material that is multiple times stronger than steel by weight provide a lightweight way of achieving tough ballistic performance at a low weight.

Cohesion

The relationship between these two pieces is critical to the performance of your armor. Without one, the other can be largely ineffective. Level III plates are a good example of this. Ultra lightweight Level III plates lack ceramic components and are constructed of 100% polyethylene. They are very strong, but are completely incapable of stopping soft steel, hardened steel, or tungsten rounds like M855, M855A1, 30-06 M2AP, M80A1, and more.

While they have their uses in maritime environments and are capable of stopping many rifle and handgun threats, they are nowhere near the performance required for the majority of military or law enforcement professionals operating in environments rich with penetrator and armor-piercing rounds. Today, a ceramic strike face is required to defeat these common higher threat rounds. You’ll find ceramic strike faces in Level III+ and Level IV products from RMA. Other manufacturers sometimes label plain old Level III plates without ceramic, “III+,” but these should not be taken seriously.

Your backer material must be adhered to the back side of your strike face for maximum performance. If these two components separate, it’s possible to see a catastrophic loss in ballistic performance. Does body armor expire? Read on.

How Can Body Armor ‘Go Bad’?

Wear & Tear

Wear and tear is natural and will happen to your gear when you use it. Typically, the signs of wear and tear are self-evident if you’re paying attention. Frayed material, holes, rips, stains, etc. all appear somewhat readily to the naked eye. However, there are less obvious things that can be done such as dropping a ceramic strike face on a hard surface like cement that can take a toll on your armor’s performance.

Being Shot

Yep, this still comes up. If your armor is shot–even once–replace it immediately. Do not bet your life on compromised armor, no matter whether it’s a hard rifle plate or soft armor vest. If you are involved in an incident and need your armor replaced, contact us with your police report. We do it at no charge.

Heat

There’s a popular myth that ceramic or polyethylene plates can degrade in heat. There’s a grain of truth to this, but it’s by no means a wide-ranging rule. Here’s the lowdown on how heat can affect body armor plates:

Heat can affect how polyethylene is adhered between layers. It can also affect how it’s adhered to the strike face of your plate. We press polyethylene using thousands of pounds of pressure at extremely high temperature cycles. This fuses dozens of layers of UHMWPE together to act as a single piece. Uniformity and cohesion created by the press cycle can be undone if not performed properly.

What Happens Then?

This plate should have laughed off any handgun round in the world. The performance difference between a pressed unit versus a much softer unpressed backer is staggering. This armor company is using a strike face smaller than the plate dimensions in order to achieve lower weight numbers. This not only means this particular plate lacks edge-to-edge protection, but also utterly fails at the most basic of tests. While it effectively defeats rounds placed in the center of the plate, it leaves the sides vulnerable. Normally we would expect the ‘cheat ring’ around the ceramic strike face to offer some ballistic resistance.

Most manufacturers that practice this will fill out the rest of the plate with extra UHMWPE. This offers Level III performance around the central III+ or IV strike face. In this case, there’s virtually no performance in the material at all due to improper pressing or no pressing at all. It simply folds out of the way of the bullet. Your backer should be pressed into something resembling a single piece, and you will see only mild separation in your backer after it’s shot. A properly pressed backer will not immediately totally separate into individual layers the way this backer does.

Delamination

Even a properly pressed backer that delaminates from the back of the strike face can see a significant loss in performance. Your backer needs to stay both intact as a single piece and uniformly adhered to the back of the strike face. Does body armor expire? If you have low-quality plates that weren’t built to stand up to regular use, maybe. Older Aramid-backed plates used to have an issue with this as well, though they are extremely uncommon today.

Do I need to worry about heat degrading the performance of my plates?

Not if you’re buying from RMA or the majority of larger, legitimate American manufacturers. There are plenty of cheap white labeled armor products on the market of questionable origin. So make sure you’re buying from a real manufacturer instead of a reseller that white labels Chinese plates. Manufacturers that have undergone NIJ Certification with a ceramic product at least once have discovered this issue before going to market with a product. A heat cycle test is performed on the armor to ensure that its performance isn’t affected by temperature during the NIJ process.

Manufacturers discover at this point that they need to change the adhesives used to adhere the backer to the strike face to be more heat-resistant. Heat can delaminate the backer off of the strike face. But this is really only a concern if you’re using cheap imported plates from manufacturers that don’t test for this. They may not have any idea that this is a possibility if all they did was pump out a plate, send it to a Youtuber to review, or send it to NTS/OBL for ballistic testing while excluding the drop, water, and heat tests before ballistic tests. They may not care if their goal from the beginning was to push as many cheap products as they could.

It Is Safe To Leave Body Armor In My Car?

Theft aside, yes. You won’t have any performance issues if your plates have been manufactured by a reputable company that practices modern armor design and manufacturing. Does body armor expire? There are no guarantees that cheap Chinese imported plates will survive. If a manufacturer has never heat cycle tested their armor or its made with an older para-aramid compound, there’s no way to know. Don’t bet your life on them.

Incentives To Test

Further, an overseas manufacturer risks virtually nothing if their product fails. A failed Chinese plate means shutting down the LLC they used to import their white labeled plate. Then simply open a new LLC, and slap a new logo on the same plate. American manufacturers could lose absolutely everything with a failure in the field. Simply put, the incentives line up for American-made products to consistently perform at a high level, and they don’t for Chinese imports. There’s no reason a factory in China focused on cranking out the cheapest possible plates would bother to look into legitimate American testing standards and spend the extra money on research and development to build a legitimately good product.

How can I tell whether my body armor is high quality or a cheap import?

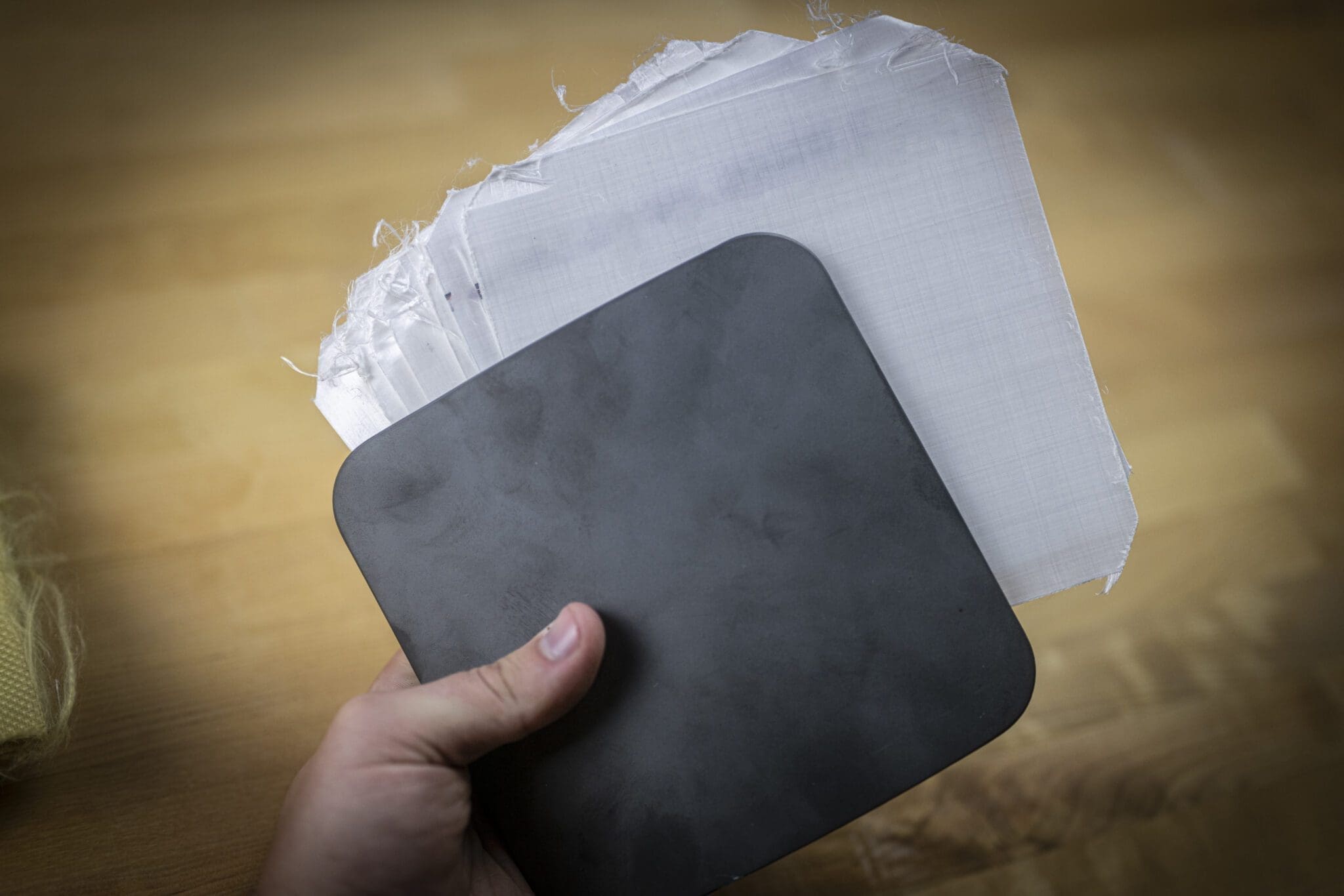

This is the most common Chinese plate on the market today. Dozens of white label retailers posing as American manufacturers sell this plate. You’ll often see these plates listed as a Boron Carbide Level IV plate that weighs 5.7 lbs. It usually retails for around $300. The biggest red flag to look for is incongruity between low weight and high price. When a plate is both extremely low weight and low price, you’re looking at a Chinese plate. Quality boron carbide plates manufactured in the United States are significantly more expensive. American-made boron carbide ceramic alone costs hundreds of dollars. Then, we process them to minimize crack propagation. Afterward, we put it into a plate with a pressed backer, adhere it at high temperatures and pressures, wrap it, and put it up for sale.

Red Flags

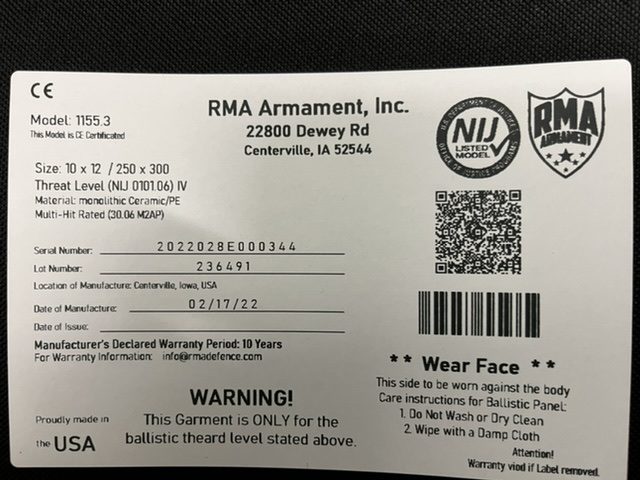

Many white label retailers don’t even know what is in their plate since they don’t manufacture it. Alumina Oxide is fairly heavy and Level 4 Alumina plates cannot (with today’s technology) crest below the 6 lb marker. If you see a sub-6 lb Level 4 plate labeled as Alumina Oxide, you’re looking at a white labeled Chinese plate. Other more obvious signs are inconsistent labeling and the words, “STRIKE FACE” printed on the front of the plate, though overseas manufacturers are getting better about making more legitimate appearances.

You may also notice dimensions in metric units or labels that lack important information such as date and location of manufacture (NOT the company’s front office or P.O. BOX/UPS Store address–you can always just look this up on Google Maps). The foam ‘bubble’ ring around the edges of Chinese plates is iconic and very common.

Counterfeit Body Armor

It’s easy and cheap manufacturing low quality plates that appear legitimate. Thus, there are lots of counterfeits that make their way out of the same factories that manufacture white label imports. We were notified of some discovered in Germany that an unscrupulous dealer was attempting to sneak into Ukrainian war supplies. You can be sure you’re getting the real deal if you buy armor made by a legitimate, reputable manufacturer and buy from an authorized dealer or factory direct.

So does body armor expire? It really all depends on whose armor you’re buying and what you’re doing to it. Remember that a manufacturer’s warranty is not an expiration of armor’s performance. It’s just a warranty. When you’re buying armor, make sure you know what you’re getting.