Affordable American Body Armor Manufacturing is Real.

Is affordable American body armor manufacturing real? Can you really get two virtually identical plates at $200 and $400? People ask us whether we’re truly American-made armor. After all, some of our pricing is dramatically more affordable than our competitors, such as our 1155 Level IV line. And we continued that tradition with our new 1165 Level IV plate, whose features outclass those of other plates that are even $100 more expensive.

You’d probably be surprised to find out that RMA Armament is the only body armor manufacturer (that we are currently aware of) that manufactures our products 100% in the United States from 100% American-made materials. Almost every manufacturer (yep, even the big ones) at least uses imported strike faces. We don’t. So how do we use all-American components, manufacture 100% in the US, and still manage to keep prices affordable? Much of this can be attributed to how a business orients itself toward the marketplace.

Simply put, RMA doesn’t price like anyone else because RMA isn’t like anyone else.

RMA Armament Sells Factory-Direct

The number one reason you see better pricing with RMA than anywhere else is because we sell factory-direct. If you’re not familiar with how everyday things you buy are priced, we’ll go over a bit of a primer here.

First, the largest customer base for body armor products by far is the US government. And it isn’t even close. For most legitimate body armor manufacturers, it only makes sense that in order to operate profitably, you need to scale your business to be a large as possible while moving enormous amounts of armor through government contracts. Because you have to scale production before delivering on high volume contracts, many body armor companies today are owned by investment firms or laden with debt that must be serviced by high volumes at high prices. Government sales are the only way to achieve this.

We bet on being different.

The truth is that consumer retail is a tough business. And the difference between selling 1000 units to a government buyer or 1000 units to individual buyers is an entirely different ball game. But we thought that since virtually nobody was selling high quality armor to the civilian market, we might have found an opening. We were right.

Sure we have a different set of hoops to jump through than most other armor companies, but we’ve been steadfast in our mission to make the best armor available to all Americans. We found that if you build it, they will come.

American Body Armor Manufacturing Business Model

Here’s the deal; you’ve probably heard other people say you’re not paying a middleman markup because you’re buying factory-direct. So what does that really mean? Let’s run some easy-to-understand numbers to illustrate it.

Manufacturers utilize a metric known as Cost of Goods to figure out a raw number for the cost of manufacturing a product in the short-term. Think of it as your grocery bill for dinner before cooking and serving it as a meal. If you spent $10 on ingredients and you were operating a restaurant, you have to deal with licensing, cleaning, labor, security, electricity, gas, maintenance, insurance, and more before you can put a dollar into your own pocket from selling that meal.

Margins

You probably have to sell that meal for $25 or $30 to profit at scale. For reference, most restaurants aim for about 20% food cost for raw margins of about 80%. Since some of these things can be variable–particularly labor–you can use COG to approximate what you’ll need to charge in order to bring a product to market.

If you’ve seen Shark Tank, you probably know that manufacturers seek about 50-70% margins in order to turn a profit. To reach those numbers, most folks manufacture overseas. In America, margins are a lot tighter due to higher taxes, regulations, labor costs, and competitive pressure from cheaper foreign goods. Margin is what is left over when you subtract your cost from your selling price. So if I sell a pair of jeans for $80 and I bought them for $40 from the manufacturer, I’ve made a 50% margin before putting money toward my other costs of doing business.

But what if you’re a manufacturer that sells to a wholesaler who then sells to a retailer that sells to the end consumer? Each of these are difficult businesses unto themselves, and many don’t want to try to practice all 3 of them simultaneously.

B2B/Wholesale

From a manufacturer’s perspective, we all survive by driving down manufacturing cost on a per-unit basis. That means American manufacturing usually only happens with very high commodity-level demand like cars, corn, gasoline, and other economic staples. With defense articles like body armor, we get a bit of an advantage since people intuitively don’t trust their lives to imported junk and government buyers don’t purchase imported junk armor since they already know better. But in order to pay for the higher costs of doing business like complicated machinery, labor, benefits, taxes, regulations, etc., we have to move a huge amount of product. Body armor traditionally hasn’t been this way outside of government sales.

Until recently, the only way to survive was to operate almost exclusively in government-only sales. And because so many buyers are municipal police departments, manufacturers needed brick-and-mortar retail dealers to do the contract bidding processes, or they would never be able to keep up. The dailies of customer service, product misuse liability, shipping individual boxes instead of pallets, coupon codes, marketing & advertising, etc. didn’t make any sense. American civilian consumers just didn’t buy body armor, while government spent a fortune on it.

The internet changed everything.

American Body Armor Manufacturing

For those that are still operating in a traditional way, the equation looks a bit like this (hypothetical numbers):

Your factory has a contract to produce 9,500 armor plates for three police departments. Your material suppliers offer volume pricing at 0-5000 (no discount on wholesale pricing), 5001-9,999 units (10% discount on pricing), and 10,000-20,000 units (15% discount). Since you need to drive down your cost in order to make a profit, you purchase the 10,000 units in order to get the extra material discount. Now, you have an extra 500 plates you need to move outside of your 9,500 unit contract that saved you an extra 5% on Cost of Goods versus buying the total number you actually needed.

But you don’t sell to the general public because it isn’t worth hiring ten more people to move just those 500 plates. So you sell those 500 plates to a small-volume internet dealer that runs a drop-shipping business through social media. This arrangement works pretty well since you’re still pushing the numbers you need and moving those extra 500 plates you couldn’t sell through normal channels. Plus, you don’t have to deal with all the headaches your dealer has with customer service and making sales.

But there’s a catch.

Cost Plus

You have multiple competing interests to wrestle with when it comes to selling in retail. Your own in-house government clients want a discounted price because they’re buying direct and in volume. Just like your suppliers, you’re offering special pricing when they make a larger order. It’s easier to deal with, and helps drive down your per-unit costs. Your dealers must have a discount on wholesale pricing so their business can turn a profit.

And at the end of the day, civilian consumers are far more price-sensitive than government buyers. They’re buying with their own money, and they’re looking to spend as little as possible. In order to handle these competing interests, manufacturers utilize pricing schemes that help to control the madness. You’re probably seen terms like MSRP and MAP before. You’ve also probably seen certain online sales where you have to add a product into your cart in order to even see a special sale price. There’s a reason for that.

MSRP

MSRP stands for Manufacturer’s Suggested Retail Price. After doing some market research, this is the selling price a manufacturer believes the product is worth. MSRP is the highest price you’ll see on anything you buy. Commonly, you’ll see retailers sell below this number, yet they all price something exactly the same price at different stores. What gives? This is known as MAP price.

MAP stands for Minimum Advertised Price. MAP price is the lowest figure a dealer is allowed to advertise a product at. Dealers are not forced to sell their goods at this price, only advertise it. So if a store puts a MAP price on a sticker instead of MSRP to show a discount to buyers, a volume buyer would probably ask for a discount on it. Because that dealer is now just selling you a product, they can do whatever they want. Once you put that item into your cart, they’re no longer advertising that price to you. They’re selling it to you.

This prevents multiple dealers of the same product from endlessly undercutting each other until they go out of business. Plus, it protects your brand’s value perception. If companies didn’t use MAP, you’d see the numbers we’re discussing next become reality, and many of your favorite stores would disappear altogether. Many manufacturers would go out of business due to an unwillingness to deal directly with individual consumers.

The biggest point to understand from a buyer’s perspective is that many other manufacturers and dealers are priced significantly higher because they are not competing for your business.

The Long Marginal Train

Now that we’ve gone over some of the generalities, let’s use a specific example to demonstrate why it is that an identical product can range in price so wildly.

- As a body armor manufacturer, you build a plate that costs $100 (COG) to build.

- You need 50% margin on balance to turn a profit after expenses at your expected volume. So, your wholesale cost to your dealer is $200.

- Your dealer buys the plates for $200 each. Because they need 30-40% margin in order to turn a profit, they price it at $300.

- However, they also must show a discount for contract buyers. Discounting from $300 would devour their margin and put them out of business. Instead, they price it at $400.

- When an agency comes calling to buy in volume, the dealer can now offer them a 25% discount down to the original price of $300.

- In this instance, you could think of this particular plate as having a MAP price of $400. When a regular consumer purchases the plate, $400 is the price they have to pay.

When you purchase factory-direct, you can purchase the very same product for only $200. There’s no difference to the factory in terms of margin. The extra $200 markup isn’t a retailer running away with the bag–it’s everyone slicing the pie in a way that keeps everyone in business.

These numbers vary given the various different ingredients, recipes, and competitive pressures in the marketplace, but the rule generally holds.

Everyone has to eat. It’s just that at RMA, a lot fewer people are at the table when you’re paying the bill.

What Makes RMA Different?

Simply put, we sell factory-direct. Your plates are packed up and shipped out about 200 feet from where they’re made. We have some dealers and we do government contracts. However, our primary business has always been oriented direct-to-consumer. That means we’re able to sell that $400 plate for only $200, and it makes no difference to our bottom line.

Competing in the government contracting space means scaling production capacity by purchasing machinery, lab testing dozens of models, and proving capability before winning any contracts, purchasing materials in volume, and delivering any product whatsoever. Thus, many of our competitors are owned by investment firms and hedge funds or laden with heavy debt loads. They have to deliver huge quantities of sales through highly efficient manufacturing to service their debt and investors, much less just turn a profit.

We scale our production and labor alongside consumer marketplace demand. Our mission statement isn’t to milk the public safety market for everything it’s worth, it’s to produce the world’s best armor for Americans. We’re unabashedly transparent, and we’re proud to say that we are one of (if not the only) 100% American-made body armor from 100% American-made materials.

American Body Armor Manufacturing Takeaways

The biggest point to understand from a buyer’s perspective is that many other American body armor manufacturers and dealers are priced significantly higher because they are not competing for your business.

They compete exclusively in the government marketplace to move 10,000 units instead of 500. What ends up for sale at internet drop ship dealers isn’t priced to woo customers. It’s priced to keep their volume dealers in business in the government contract market. They, they move excess inventory to keep per-unit manufacturing costs low. It’s that simple. It isn’t because RMA isn’t American-made. In fact we’re far more American-made than our competitors that import strike faces and materials.

What about the other companies that aren’t the big guys working government contracts? Straight up, they’re just ripping you off. They could offer you a high quality plate made from American components. They just don’t want to bother getting their own machinery and doing it correctly. Why would you, if your business is successfully tricking people into betting their life on cheap Chinese plates and you’re making money hand over fist?

Conclusion

Still not sure about RMA? Go ahead and find our factory on Google Maps. It isn’t a UPS Store mailbox, a virtual office, or our mom’s house. It isn’t a furniture showroom in Missouri, or a 1000 sq ft office rental shared with 5 other businesses (these are all existing real-world examples of other armor business addresses). That is, if they allow you to see any address at all (why are they always hiding it?).

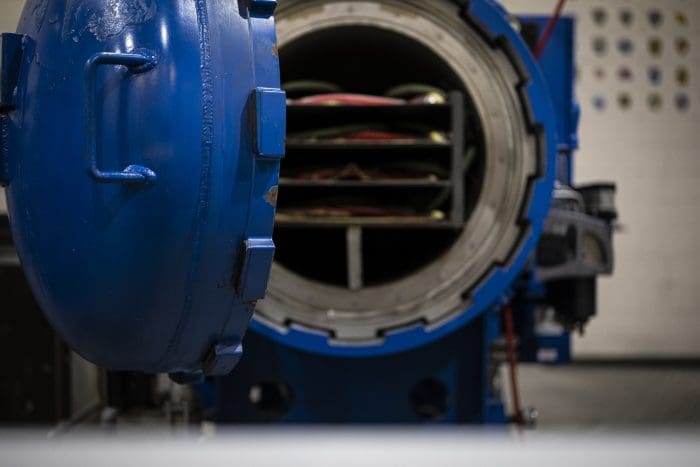

We’re a small American body armor manufacturing business owned by Blake Waldrop, a former Marine and police officer. He lives in Centerville, IA a few miles from the factory. You can meet him and he’ll show you the factory. Our factory address is 22800 Dewey Rd Centerville, IA 52544. If you want to come by for a tour, let us know. We’ll show you where and how we make the armor you’re trusting your life to. Once you see what it takes to manufacture high quality body armor in the United States, you’ll be able to see through the fake armor businesses selling white labeled Chinese junk by just searching for their address.

There’s no reason to trust your life to cheap Chinese junk when you can buy American body armor manufacturing quality for such low prices. And there’s no reason to buy other plates with imported parts. Parts that are overpriced because they’re not even trying to be affordable for you. Don’t trust your life to a mystery box of questionable origin. Buy American.